Introduction

The construction industry faces a fundamental challenge: projects are complex, involve multiple disciplines, and traditional processes rely heavily on paper documents and disconnected workflows. Virtual Design and Construction (VDC) emerged as a response to these challenges, fundamentally changing how we plan, design, and build structures.

What is Virtual Design and Construction?

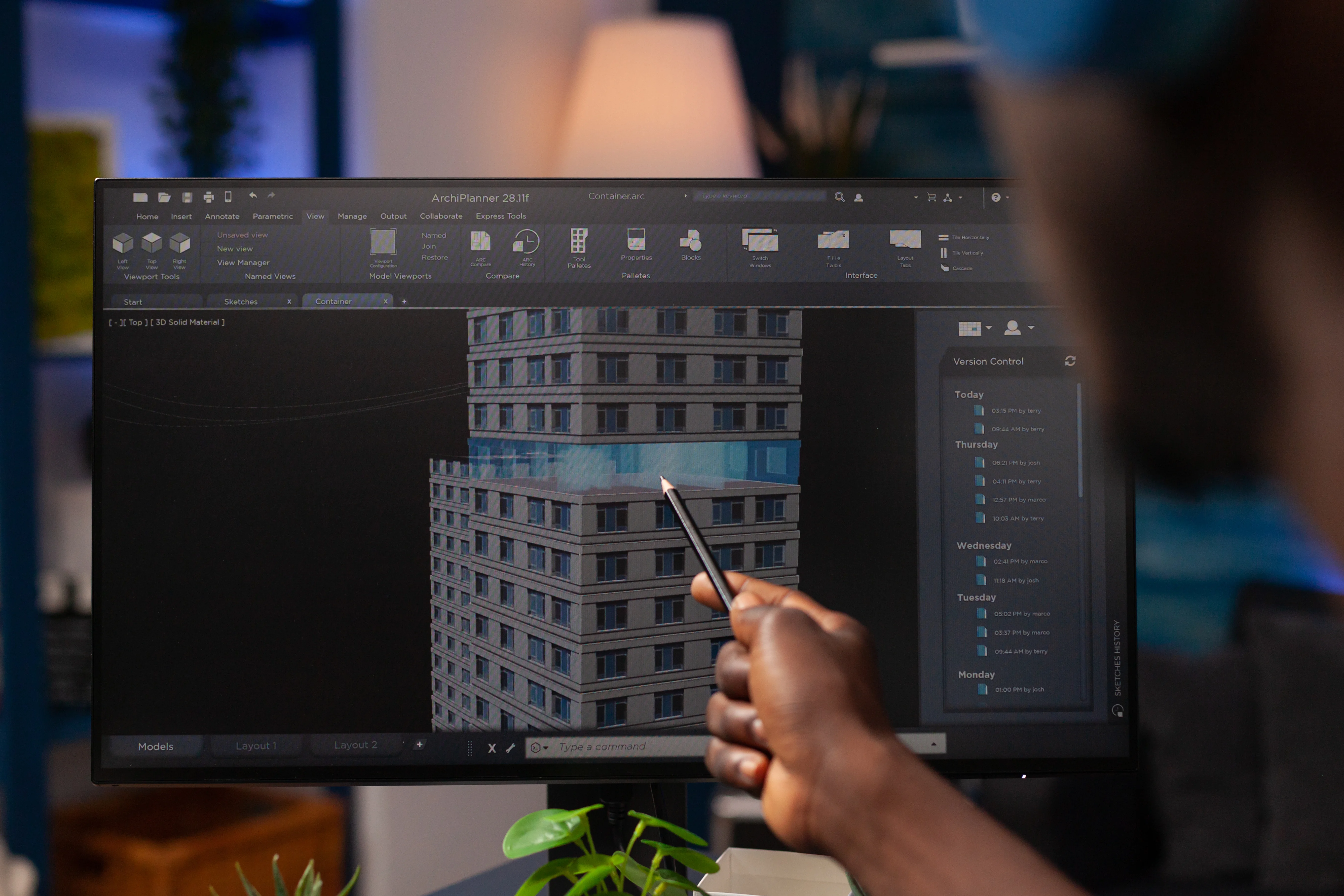

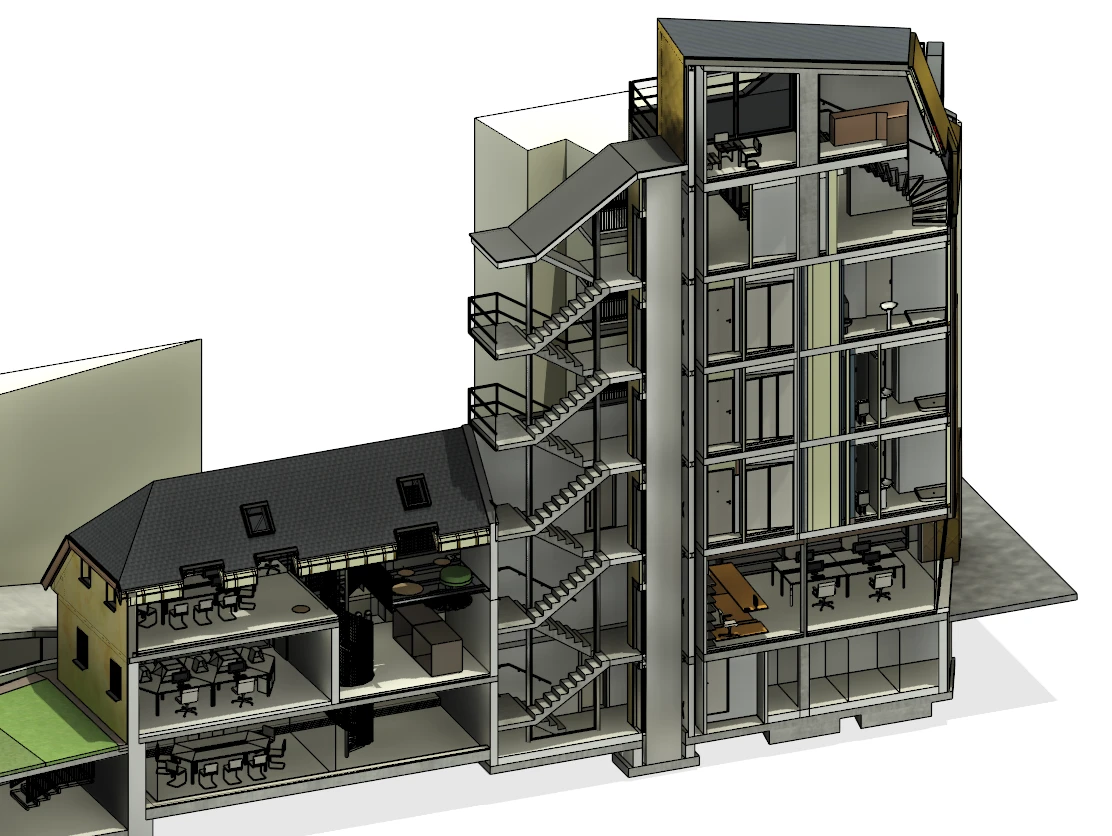

Virtual Design and Construction is a methodology that integrates people, processes, and product models throughout the entire construction lifecycle. In the simplest terms, VDC means building the project once digitally to identify and solve problems, then building it more efficiently in the physical world.

VDC was developed by researchers at Stanford University's Center for Integrated Facility Engineering (CIFE) in 2001, though its conceptual roots reach back to 1976. Unlike traditional approaches where planning and design are rushed to start construction quickly, VDC front-loads critical decision-making to the beginning of the process, when it's easier to reduce risk, assess performance, and mitigate cost and schedule overruns.

Why VDC Was Needed

The Productivity Problem

Construction processes haven't evolved significantly in recent decades. According to the 2021 JB Knowledge ConTech Survey, 45% of project management workflows still rely on spreadsheets. While spreadsheets are powerful tools, they're highly fallible for managing the complexity and dynamism of large construction projects.

Paper-based documents and spreadsheets create several critical problems:

- They slow down decision-making and planning

- Single changes can cascade through schedules, labor needs, equipment, and costs

- Days are lost capturing changes and assessing their impact

- Labor productivity suffers when construction is already underway

- Data integrity is compromised across disconnected systems

The Paulson Curve: A Foundational Insight

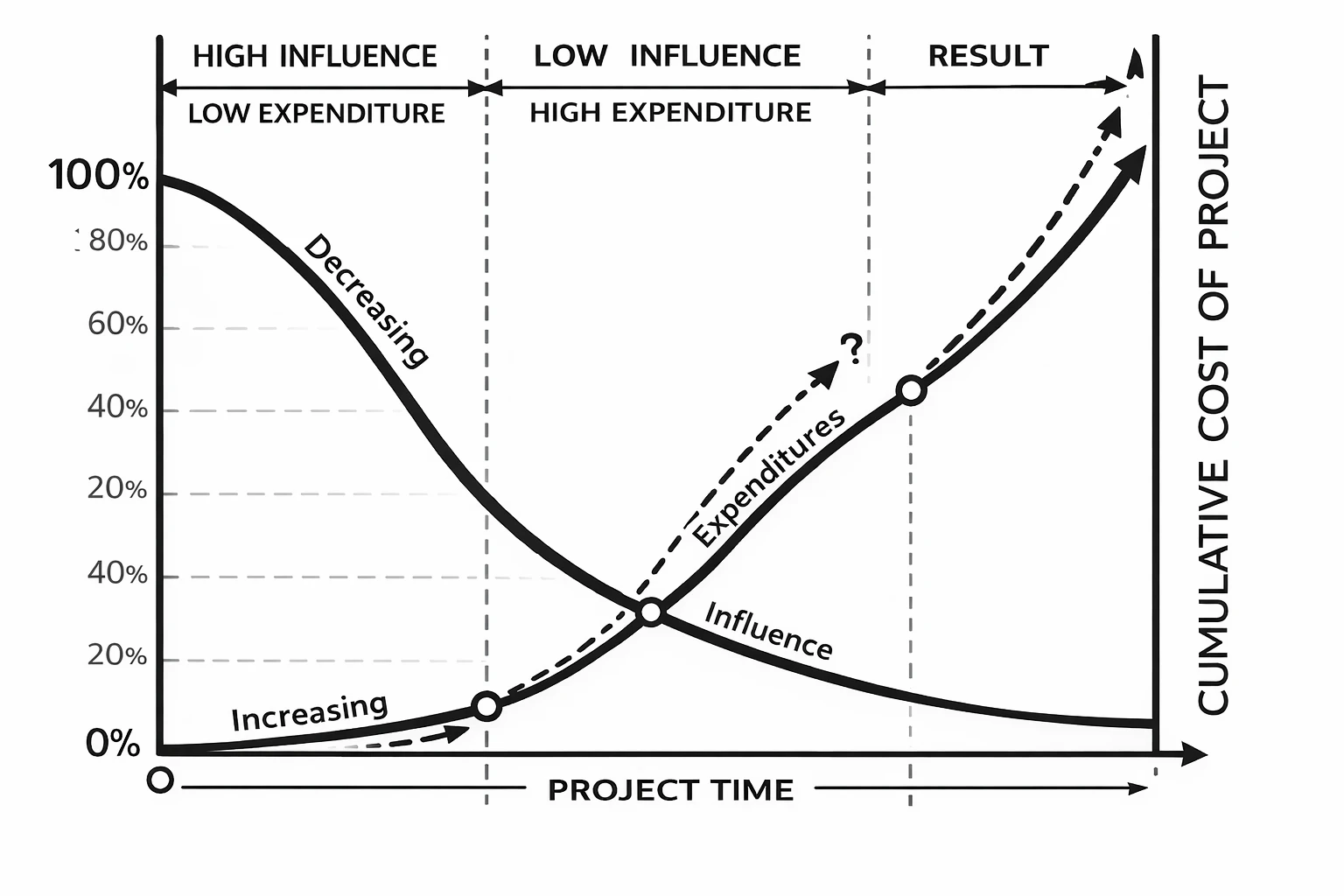

In 1976, Stanford Professor Boyd Paulson published a groundbreaking paper entitled "Designing to Reduce Construction Costs." Paulson identified a structural problem: decisions made early in a project, when costs are still low, have extraordinary effects on the final cost, yet traditionally, little attention is paid to such implications during this phase.

Paulson created what would later become known as the "Level of Influence Curve" (often incorrectly attributed to Patrick MacLeamy of HOK in 2004). This diagram shows intersecting cost and influence curves, illustrating that the ability to impact project outcomes is highest at the beginning when costs are lowest, and decreases as the project progresses while costs increase.

This insight became the core principle of what would eventually become Integrated Project Delivery (IPD) as a strategy and VDC as the execution method.

The VDC Framework

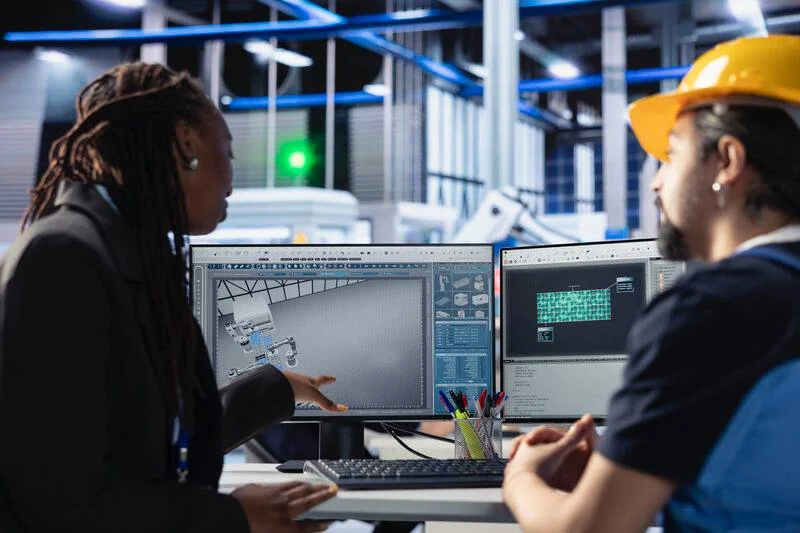

The Building Construction Authority of Singapore provides one of the most straightforward frameworks for understanding VDC. Construction teams create virtualized construction models and timelines to translate concepts, expectations, and performance goals into the most effective plan possible.

Key Characteristics of VDC Models

VDC models possess several essential characteristics:

-

Holistic Focus: They consider the asset itself, the teams that will define, design, construct and operate it, and the process they will follow

-

Integration: Models are integrated so that data is shareable and can capture dependencies to relevant models when a user makes a change

-

Predictive Capability: They can predict aspects of project performance and show how it relates to project performance objectives

-

Flexibility: Models are interactive, allowing all project stakeholders to glean the information they need

VDC Tools and Technologies

To create these models, construction teams use:

- Product and process modeling tools

- Organizational visualization software

- Online collaboration tools

- 3D/4D/5D BIM software

- Laser scanning and reality capture with drones

- Machine learning and AI optimization

These technologies enable teams to generate photo-realistic representations of built spaces, perform clash detection, coordinate multiple trades, evaluate site logistics and sequencing, and determine the most efficient approach to construction.

VDC vs. BIM: Understanding the Difference

VDC and Building Information Modeling (BIM) are commonly confused, but there are distinct differences. BIM may be a component of VDC, but they're not synonymous.

BIM focuses primarily on creating a digital model of a physical asset. Higher levels of BIM can incorporate scheduling, cost, and project lifecycle information, but they don't necessarily encompass the people and processes involved in a project.

VDC is broader—it focuses on planning the best approach to deliver a construction project, including scheduling, cost, risk management, the integration of multidisciplinary teams from the earliest stages. VDC may incorporate BIM, but it can also exist without it.

Major Benefits of Virtual Design and Construction

1. Improved Worker and End-User Safety

The realism and detail offered by VDC models enable design teams to forecast hazards more accurately. When safety considerations are integrated from the beginning:

- Potential hazards can be identified before construction begins

- Design can be modified to reduce or eliminate risks

- Contractors can train teams based on accurate hazard information

- Both worker safety and end-user safety improve

2. Enhanced Communication

VDC enables non-technical stakeholders—government leaders, executives without technical backgrounds, and members of the general public—to understand project intent through easy-to-interpret images and animations. This democratization of project information leads to better-informed decision-making across all levels.

3. Risk Reduction

Traditional risk management relies heavily on experience and expertise, but every project is different. VDC empowers construction teams to accurately foresee the potential risks specific to each project. Research from Mortenson Construction shows they were able to reduce schedules by 32 days on average using VDC, demonstrating the tangible impact of better risk management.

4. Sustainability Planning

As the construction sector tackles sustainability challenges, VDC enables project teams to:

- Assess energy efficiency and carbon emissions

- Evaluate embodied carbon in materials and construction processes

- Plan for adaptive reuse and future modifications

- Simulate different energy scenarios and renewable energy integration

- Consider grid flexibility and onsite storage

Studies show that adaptive reuse, when properly planned, can reduce embodied carbon by 33%. VDC makes it possible to incorporate these considerations during initial design rather than as costly retrofits.

Challenges and Industry Adoption

Despite its proven benefits, VDC adoption faces several challenges:

Investment vs. Return

As Derek Cunz of Mortenson notes, "There's not a punishment for lack of innovation...no one sees the downside, yet." Without clear disincentives for traditional methods, companies may resist investing in new execution methods.

Long Project Cycles

Traditional project delivery means that incremental change comes slowly, regardless of innovative practices.

Cultural Resistance

The industry must become more open to change and more willing to ask challenging questions about established practices.

Skills Gap

Implementing VDC requires new skills and knowledge that many firms are still developing.

The Future of VDC

AI and Machine Learning

Tools like ALICE demonstrate how AI can optimize construction sequences, but this is just the beginning. Future applications will likely include:

- Automated design optimization

- Predictive maintenance planning

- Real-time decision support systems

Digital Twins

The convergence of VDC with Internet of Things (IoT) sensors and real-time data will create living digital twins of buildings and infrastructure, enabling continuous optimization throughout the asset lifecycle.

Augmented and Virtual Reality

AR and VR technologies will make VDC models more accessible and useful on job sites, allowing workers to visualize completed work and identify issues in real-time.

Implementing VDC: Best Practices

Start Early

The earlier VDC is incorporated into a project, the greater its impact. Ideally, VDC should begin during conceptual design.

Invest in Training

Team members need proper training to leverage VDC tools effectively. This includes both technical skills and understanding of integrated project delivery principles.

Choose the Right Projects

Complex projects with multiple stakeholders and tight schedules benefit most from VDC. Start with projects where the value proposition is clearest.

Foster Collaboration

VDC succeeds when all stakeholders—owners, designers, contractors, and subcontractors—participate actively. Create collaborative environments and incentive structures that reward information sharing.

Measure and Learn

Track metrics like schedule reduction, cost savings, safety incidents, and rework to demonstrate VDC's value and identify areas for improvement.

Conclusion

Virtual Design and Construction represents a fundamental shift in how the construction industry approaches projects. By moving planning and decision-making to the beginning of the process and leveraging digital integration, VDC addresses construction's biggest challenges: productivity, safety, sustainability, and transparency.

From its origins at Stanford CIFE in the work of Boyd Paulson to today's AI-powered optimization tools, VDC has evolved from an academic concept to an industry necessity. While challenges remain in widespread adoption, the benefits are clear: reduced risk, improved safety, better sustainability outcomes, and more efficient project delivery.

As the construction sector continues to digitize and as technologies like AI, machine learning, and digital twins mature, VDC will become even more powerful. The future may extend beyond individual buildings to entire communities and cities, transforming not just how we build, but how we plan and manage the built environment at every scale.

For construction professionals looking to stay competitive and deliver better projects, understanding and implementing VDC is no longer optional—it's essential. As Martin Fischer, Director of CIFE, puts it: "We challenge the industry and the industry challenges us." This continuous dialogue between research and practice, between theory and application, ensures that VDC will continue to evolve and address the industry's most pressing needs.